Understanding the Benefits of Bowl Buckle Scaffolding in Construction

Understanding the Benefits of Bowl Buckle Scaffolding in Construction

Bowl buckle scaffolding has emerged as a pivotal component in modern construction, providing a versatile and reliable solution for building projects of all sizes. With its unique design and structural integrity, this scaffolding type offers numerous benefits that enhance safety, efficiency, and adaptability on construction sites

Understanding the Benefits of Bowl Buckle Scaffolding in Construction

Bowl buckle scaffolding has emerged as a pivotal component in modern construction, providing a versatile and reliable solution for building projects of all sizes. With its unique design and structural integrity, this scaffolding type offers numerous benefits that enhance safety, efficiency, and adaptability on construction sites. In this comprehensive article, we will explore the multifaceted advantages of bowl buckle scaffolding, its features, safety considerations, and its role in modern construction practices.

Table of Contents

1. Introduction to Bowl Buckle Scaffolding

2. Advantages of Bowl Buckle Scaffolding

2.1 Enhanced Stability and Load Capacity

2.2 Versatile Design for Various Applications

2.3 Quick Assembly and Disassembly

2.4 Cost-Effectiveness and Durability

3. Safety Features of Bowl Buckle Scaffolding

3.1 Compliance with Safety Standards

3.2 Improved Worker Safety Measures

4. Comparison with Other Scaffolding Types

4.1 Frame Scaffolding vs. Bowl Buckle Scaffolding

4.2 System Scaffolding vs. Bowl Buckle Scaffolding

5. Key Components of Bowl Buckle Scaffolding

6. Installation Guidelines and Best Practices

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction to Bowl Buckle Scaffolding

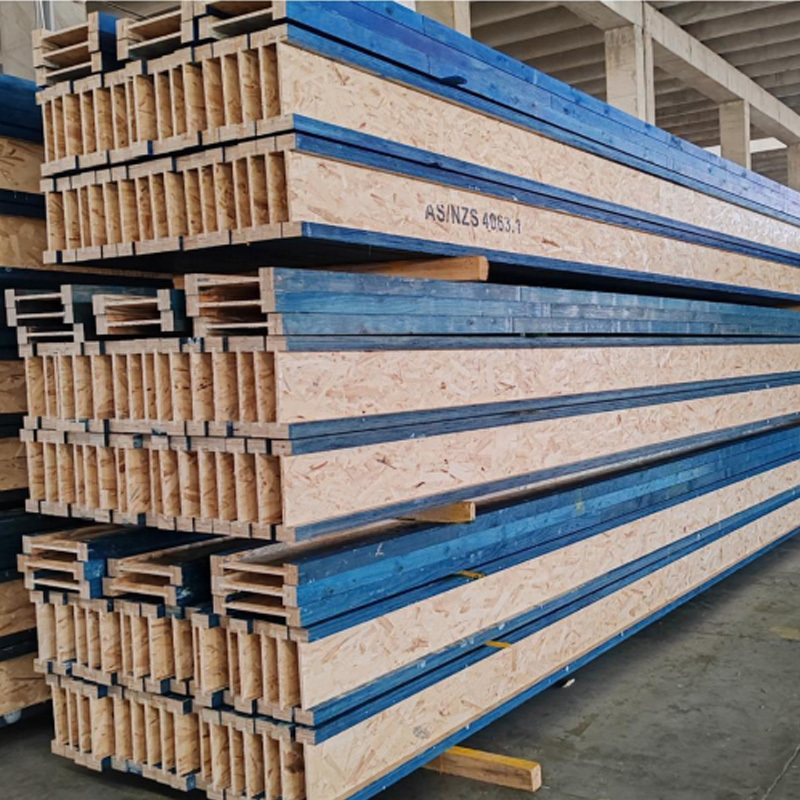

Bowl buckle scaffolding is a type of modular scaffolding that utilizes a bowl and pin system to connect vertical and horizontal components. This innovative design allows for easy adjustments, making it suitable for various construction applications, from residential buildings to large-scale industrial projects. The bowl buckle system not only simplifies the assembly process but also enhances the overall stability of the structure, making it a preferred choice among construction professionals.

2. Advantages of Bowl Buckle Scaffolding

The benefits of bowl buckle scaffolding are numerous, contributing to its widespread adoption in the construction industry. Below, we delve deeper into the key advantages that make this scaffolding system stand out.

2.1 Enhanced Stability and Load Capacity

One of the most significant benefits of bowl buckle scaffolding is its enhanced stability. The unique bowl and pin connection system allows for secure locking of components, ensuring that the scaffold remains stable under various load conditions. This stability is crucial when working at heights, as it minimizes the risk of accidents and structural failures.

Additionally, bowl buckle scaffolding is designed to support heavy loads, making it suitable for projects that involve substantial materials and equipment. The system's load-bearing capacity is particularly beneficial in industrial settings, where scaffolding may need to support heavy machinery or construction materials.

2.2 Versatile Design for Various Applications

Bowl buckle scaffolding is highly versatile, making it adaptable to different construction situations. Whether it’s for residential construction, high-rise buildings, or complex industrial projects, this scaffolding can be customized to meet specific requirements. The modular design allows for easy adjustments in height and configuration, enabling construction teams to tackle diverse challenges efficiently.

2.3 Quick Assembly and Disassembly

Time is a critical factor in construction projects, and bowl buckle scaffolding excels in this area. The quick assembly and disassembly process reduces labor costs and accelerates project timelines. Construction teams can erect or dismantle the scaffold in a fraction of the time compared to traditional scaffolding systems, ensuring that work progresses smoothly.

2.4 Cost-Effectiveness and Durability

Investing in bowl buckle scaffolding proves to be cost-effective in the long run. The durability of the materials used in its construction means that it can withstand harsh weather conditions and heavy usage without compromising structural integrity. This longevity reduces the need for frequent replacements, thereby saving costs associated with buying new scaffolding components.

3. Safety Features of Bowl Buckle Scaffolding

Safety is paramount in the construction industry, and bowl buckle scaffolding is designed with several safety features to protect workers and ensure compliance with industry regulations.

3.1 Compliance with Safety Standards

Bowl buckle scaffolding adheres to international safety standards, ensuring that it meets the necessary requirements for use in construction projects. Compliance with these standards not only protects workers but also minimizes the risk of legal issues for construction companies.

3.2 Improved Worker Safety Measures

The design of bowl buckle scaffolding includes features that enhance worker safety. The secure locking mechanism prevents accidental disassembly while in use, and the sturdy base reduces the likelihood of tipping. Additionally, many bowl buckle scaffolding systems come equipped with guardrails and toe boards to provide further protection for workers working at heights.

4. Comparison with Other Scaffolding Types

To appreciate the unique benefits of bowl buckle scaffolding, it’s essential to compare it with other common scaffolding types.

4.1 Frame Scaffolding vs. Bowl Buckle Scaffolding

Frame scaffolding is one of the most common types used in construction. While it offers a straightforward assembly process, it lacks the stability and load capacity provided by bowl buckle scaffolding. The connection points in frame scaffolding are often less secure, making bowl buckle scaffolding a safer alternative for high-load applications.

4.2 System Scaffolding vs. Bowl Buckle Scaffolding

System scaffolding is designed for quick use but often requires specific components that may not be as readily available. In contrast, bowl buckle scaffolding utilizes a universal component system, allowing for greater flexibility in use. The adaptability and ease of assembly of bowl buckle scaffolding make it a more practical choice for many construction scenarios.

5. Key Components of Bowl Buckle Scaffolding

Understanding the components of bowl buckle scaffolding is essential for effective use. The main parts include:

- **Vertical Standards**: These are the vertical posts that bear the weight of the scaffold.

- **Horizontal Ledgers**: These are horizontal supports that connect the vertical standards.

- **Bowl Buckles**: The unique fastening system that locks the components in place.

- **Planks or Decks**: The surfaces on which workers stand and materials are placed.

- **Braces**: Diagonal supports that provide additional stability.

Each component plays a vital role in ensuring the overall safety and effectiveness of the scaffolding system.

6. Installation Guidelines and Best Practices

Proper installation of bowl buckle scaffolding is crucial for maintaining safety and efficiency. Here are some best practices to consider:

1. **Assess Site Conditions**: Before installation, evaluate the soil stability and environment to ensure the scaffold will be secure.

2. **Follow Manufacturer Instructions**: Adhere strictly to the manufacturer’s guidelines for assembly and disassembly to prevent accidents.

3. **Regular Inspections**: Conduct routine checks of the scaffold structure to identify any wear or damage that may affect safety.

4. **Training for Workers**: Ensure that all workers involved in the assembly and use of bowl buckle scaffolding are adequately trained on safety protocols and operational procedures.

7. Frequently Asked Questions (FAQs)

Q1: What is bowl buckle scaffolding?

A1: Bowl buckle scaffolding is a modular scaffolding system that uses a bowl and pin mechanism for secure connections between vertical and horizontal components, providing stability and adaptability for various construction applications.

Q2: How does bowl buckle scaffolding compare to traditional scaffolding?

A2: Bowl buckle scaffolding offers enhanced stability, load capacity, and faster assembly compared to traditional scaffolding systems, making it a safer and more efficient choice for construction projects.

Q3: Is bowl buckle scaffolding safe for use at heights?

A3: Yes, bowl buckle scaffolding is designed with safety features that comply with industry standards, including secure locking mechanisms and added protective measures for workers.

Q4: Can bowl buckle scaffolding be used in all types of construction projects?

A4: Yes, bowl buckle scaffolding is versatile and can be used for a wide range of construction applications, from residential buildings to large industrial projects.

Q5: What maintenance is required for bowl buckle scaffolding?

A5: Regular inspections for wear and damage, along with prompt repairs and adherence to safety guidelines, are essential for maintaining the integrity and safety of bowl buckle scaffolding.

8. Conclusion

Bowl buckle scaffolding has proven to be a game-changer in the construction industry, offering a blend of stability, versatility, and safety that enhances the efficiency of work at heights. Its innovative design, coupled with cost-effectiveness and durability, makes it an ideal choice for a variety of construction projects. By understanding the benefits and best practices associated with bowl buckle scaffolding, construction professionals can ensure a safer and more productive work environment. As the industry continues to evolve, embracing advanced scaffolding solutions like bowl buckle scaffolding will be crucial for achieving optimal results in construction endeavors.

TAG:

Next

Related News

Why Hot Dip Galvanized Steel Springboards Are Essential for Construction Projects

Why Hot Dip Galvanized Steel Springboards Are Essential for Construction Projects

Introduction to Hot Dip Galvanized Steel Springboards

In the ever-evolving landscape of construction, choosing the right materials is crucial. Among these, **hot dip galvanized steel springboards** stand out as an indispensable element in modern construction methodologies. They provide a unique blend of strength, dur