Why Hot Dip Galvanized Steel Springboards Are Essential for Construction Projects

Why Hot Dip Galvanized Steel Springboards Are Essential for Construction Projects

Introduction to Hot Dip Galvanized Steel Springboards

In the ever-evolving landscape of construction, choosing the right materials is crucial. Among these, **hot dip galvanized steel springboards** stand out as an indispensable element in modern construction methodologies. They provide a unique blend of strength, dur

Why Hot Dip Galvanized Steel Springboards Are Essential for Construction Projects

Introduction to Hot Dip Galvanized Steel Springboards

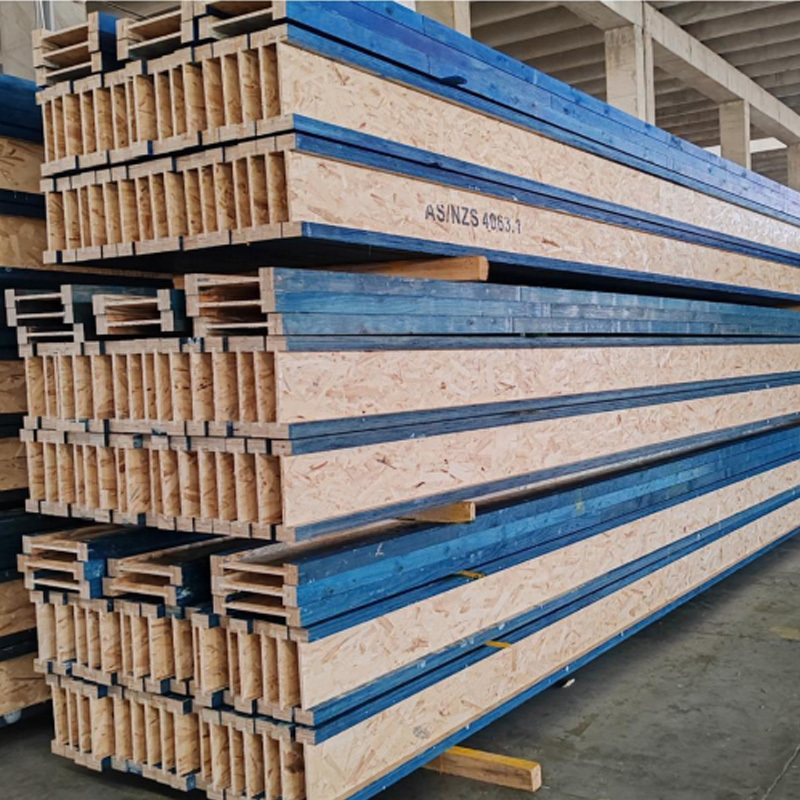

In the ever-evolving landscape of construction, choosing the right materials is crucial. Among these, **hot dip galvanized steel springboards** stand out as an indispensable element in modern construction methodologies. They provide a unique blend of strength, durability, and corrosion resistance, making them an essential choice for construction projects of various scales.

Understanding Hot Dip Galvanization

What is Hot Dip Galvanization?

**Hot dip galvanization** is a process in which steel is submerged in molten zinc, creating a robust protective coating. This method ensures long-lasting protection against rust and corrosion, significantly extending the lifespan of steel structures. The process begins with cleaning the steel surface, followed by immersion in molten zinc at temperatures exceeding 400 degrees Celsius.

Benefits of Hot Dip Galvanized Steel

The benefits of using hot dip galvanized steel are numerous:

- **Corrosion Resistance**: The zinc coating acts as a barrier against moisture and other corrosive elements.

- **Durability**: Hot dip galvanized steel can last for decades, even in harsh environments.

- **Low Maintenance**: Minimal upkeep is required, reducing overall project costs.

- **Eco-Friendly**: The zinc coating can be recycled, making it a sustainable choice.

The Importance of Springboards in Construction

Defining Steel Springboards

**Steel springboards** are crucial components in many construction projects. They provide a temporary working platform for construction workers, ensuring safety and mobility while performing tasks at elevated heights.

Key Functions of Springboards

- **Supporting Workers**: Springboards offer secure footing for workers, enhancing safety on job sites.

- **Increasing Efficiency**: By providing stable platforms, they allow workers to perform tasks more efficiently without the constant need to climb up and down ladders or scaffolding.

- **Facilitating Material Handling**: Springboards serve as staging areas for materials, tools, and equipment, streamlining the construction process.

The Unique Advantages of Hot Dip Galvanized Steel Springboards

Enhanced Safety Features

Safety is paramount in construction. **Hot dip galvanized steel springboards** offer several safety benefits:

- **Slip Resistance**: Their textured surfaces minimize the risk of slipping, ensuring a secure standing area.

- **Load-Bearing Capability**: These springboards can withstand significant weight, providing a reliable platform for multiple workers and their tools.

Cost-Effectiveness Over Time

Investing in hot dip galvanized steel springboards translates to long-term savings. Though the initial cost may be higher than other materials, the reduced need for replacement and maintenance leads to substantial savings over the lifespan of the product.

Applications of Hot Dip Galvanized Steel Springboards

Residential Construction

In residential projects, these springboards are commonly used for roofing, siding, and other elevated tasks. Their ability to withstand the elements ensures that workers can operate safely and effectively.

Commercial and Industrial Construction

For larger commercial projects, hot dip galvanized steel springboards are essential for scaffolding systems. Their robustness allows for extensive use across multiple floors, facilitating complex construction operations.

Infrastructure Development

In infrastructure projects such as bridges and highways, the durability of hot dip galvanized steel springboards is vital. These structures often face harsh weather conditions, making corrosion resistance a key factor in material selection.

Installation and Maintenance of Hot Dip Galvanized Steel Springboards

Proper Installation Techniques

Installing hot dip galvanized steel springboards requires careful planning and execution. Key steps include:

1. **Surface Preparation**: Ensure all surfaces are clean and free of debris.

2. **Secure Attachment**: Use appropriate fastening methods to firmly attach the springboard to the main structure.

3. **Inspections**: Conduct regular inspections to ensure stability and safety.

Maintenance Guidelines

While hot dip galvanized steel springboards are low maintenance, periodic checks for any signs of wear or damage are essential. Cleaning the surfaces to remove any debris or buildup will help maintain their integrity over time.

Frequently Asked Questions (FAQs)

1. What is the lifespan of hot dip galvanized steel springboards?

The lifespan can exceed 30 years, depending on environmental conditions and usage.

2. Are hot dip galvanized steel springboards suitable for outdoor use?

Yes, their corrosion resistance makes them ideal for outdoor applications.

3. How do I ensure the safety of my workers when using springboards?

Regular inspections, proper installation, and adhering to safety guidelines are crucial.

4. Can hot dip galvanized steel springboards be recycled?

Yes, they can be recycled due to the zinc coating, contributing to sustainable construction practices.

5. What factors should I consider when selecting springboards for my project?

Consider load capacity, environmental conditions, and the specific tasks to be performed.

Conclusion

In conclusion, **hot dip galvanized steel springboards** are not just an option; they are an essential component in modern construction projects. With their superior durability, corrosion resistance, and safety features, they offer undeniable advantages that enhance construction efficiency and worker safety. Investing in these springboards is a strategic decision that pays off through reduced maintenance costs and increased longevity. As construction techniques continue to evolve, the reliance on high-quality materials like hot dip galvanized steel springboards will undoubtedly grow, solidifying their place as a cornerstone in the industry.

TAG:

Related News

Why Hot Dip Galvanized Steel Springboards Are Essential for Construction Projects

Why Hot Dip Galvanized Steel Springboards Are Essential for Construction Projects

Introduction to Hot Dip Galvanized Steel Springboards

In the ever-evolving landscape of construction, choosing the right materials is crucial. Among these, **hot dip galvanized steel springboards** stand out as an indispensable element in modern construction methodologies. They provide a unique blend of strength, dur