Understanding H20 Beam for Formwork Support: A Key Component in Modern Construction

In the construction and decoration materials industry, the H20 beam plays a pivotal role in formwork support systems. Designed specifically for use in temporary structures, these beams offer unparalleled strength and stability to support concrete during the curing process. The H20 beam's design is characterized by its lightweight yet robust structure, which is made from engineered wood and reinfor

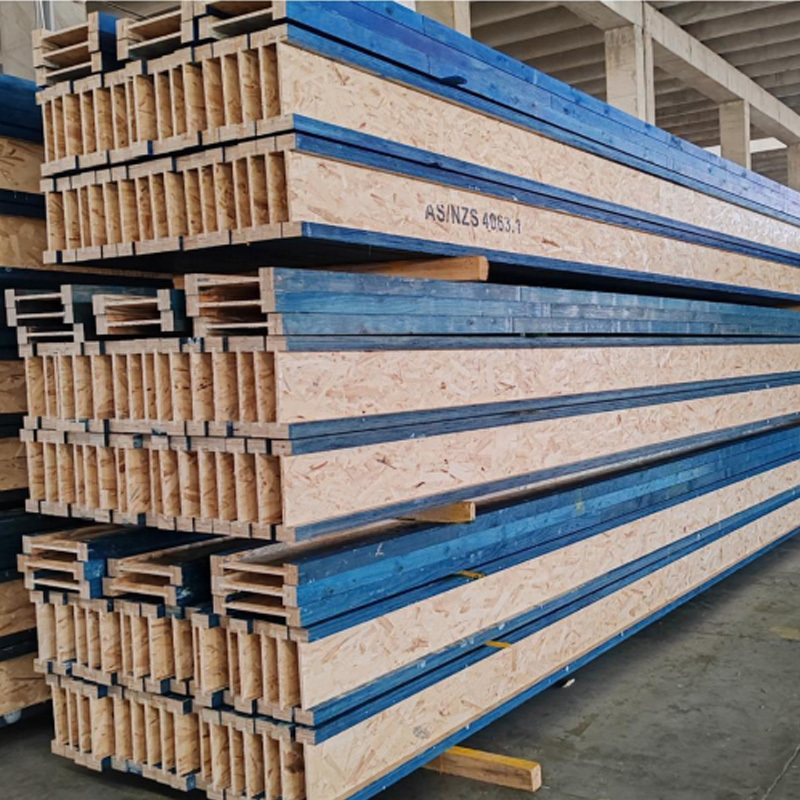

In the construction and decoration materials industry, the H20 beam plays a pivotal role in formwork support systems. Designed specifically for use in temporary structures, these beams offer unparalleled strength and stability to support concrete during the curing process. The H20 beam's design is characterized by its lightweight yet robust structure, which is made from engineered wood and reinforced with a steel web. This unique combination provides excellent load-bearing capacity and resistance to deformation, making it an ideal choice for various construction applications.

One of the primary advantages of H20 beams is their versatility. They can be easily customized to fit different project requirements, whether for residential buildings, commercial complexes, or infrastructure projects. This adaptability allows construction teams to efficiently design and implement formwork systems that cater to the specific needs of a project, optimizing both time and resources.

Another significant benefit of H20 beams is their ease of handling. Weighing considerably less than traditional steel beams, H20 beams can be transported and installed with minimal effort. This feature not only enhances labor efficiency but also reduces the risk of workplace injuries associated with heavy lifting. The lightweight nature of these beams, combined with their high strength-to-weight ratio, allows for quicker assembly and disassembly of formwork systems, consequently speeding up the overall construction timeline.

The environmental aspect of H20 beams should also be highlighted. Being manufactured from renewable materials, these beams contribute to sustainable construction practices. Their production processes are often designed to minimize waste and energy consumption, aligning with the growing demand for environmentally friendly building materials in the construction industry.

Furthermore, H20 beams possess excellent dimensional stability, which is crucial when dealing with concrete forms. They resist warping and cracking, ensuring consistent performance throughout the project lifecycle. This reliability helps maintain the integrity of the formwork, leading to better-quality concrete finishes and reducing the likelihood of costly repairs or rework.

In conclusion, H20 beams for formwork support are an essential component of modern construction practices. Their lightweight design, versatility, ease of handling, and environmental benefits make them a preferred choice among construction professionals. By understanding the importance of H20 beams, builders and contractors can make informed decisions that enhance the efficiency and sustainability of their projects. As the construction industry continues to evolve, the role of innovative materials like H20 beams will undoubtedly become more prominent, shaping the future of building practices.

One of the primary advantages of H20 beams is their versatility. They can be easily customized to fit different project requirements, whether for residential buildings, commercial complexes, or infrastructure projects. This adaptability allows construction teams to efficiently design and implement formwork systems that cater to the specific needs of a project, optimizing both time and resources.

Another significant benefit of H20 beams is their ease of handling. Weighing considerably less than traditional steel beams, H20 beams can be transported and installed with minimal effort. This feature not only enhances labor efficiency but also reduces the risk of workplace injuries associated with heavy lifting. The lightweight nature of these beams, combined with their high strength-to-weight ratio, allows for quicker assembly and disassembly of formwork systems, consequently speeding up the overall construction timeline.

The environmental aspect of H20 beams should also be highlighted. Being manufactured from renewable materials, these beams contribute to sustainable construction practices. Their production processes are often designed to minimize waste and energy consumption, aligning with the growing demand for environmentally friendly building materials in the construction industry.

Furthermore, H20 beams possess excellent dimensional stability, which is crucial when dealing with concrete forms. They resist warping and cracking, ensuring consistent performance throughout the project lifecycle. This reliability helps maintain the integrity of the formwork, leading to better-quality concrete finishes and reducing the likelihood of costly repairs or rework.

In conclusion, H20 beams for formwork support are an essential component of modern construction practices. Their lightweight design, versatility, ease of handling, and environmental benefits make them a preferred choice among construction professionals. By understanding the importance of H20 beams, builders and contractors can make informed decisions that enhance the efficiency and sustainability of their projects. As the construction industry continues to evolve, the role of innovative materials like H20 beams will undoubtedly become more prominent, shaping the future of building practices.

TAG:

Related News

Why Hot Dip Galvanized Steel Springboards Are Essential for Construction Projects

Why Hot Dip Galvanized Steel Springboards Are Essential for Construction Projects

Introduction to Hot Dip Galvanized Steel Springboards

In the ever-evolving landscape of construction, choosing the right materials is crucial. Among these, **hot dip galvanized steel springboards** stand out as an indispensable element in modern construction methodologies. They provide a unique blend of strength, dur