quality Hot Dip Galvanized Steel Springboard

Hot-Dip Galvanized Steel Springboard is playing a vital role in numerous fields, including construction and shipbuilding, thanks to its outstanding performance.

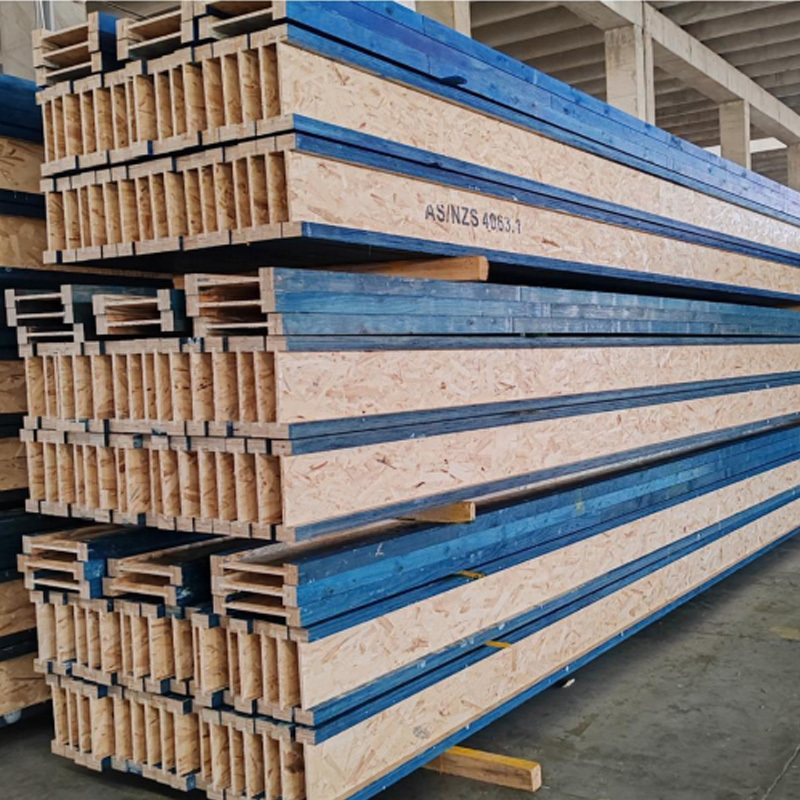

Appearance and Basic Structure

Hot-Dip Galvanized Steel Springboard features a uniform, shiny silver zinc coating, which is not only aesthetically pleasing but also provides reliable protection. It features a regular plate structure and is available in a variety of sizes to meet diverse construction needs. Anti-slip grooves are designed on the board surface to effectively increase friction and reduce the risk of slips. Connecting and securing devices are installed at both ends, facilitating the creation of a stable working platform.

Core Process - Hot-Dip Galvanizing

Hot-dip galvanizing is a key manufacturing process for this springboard. The steel springboard is immersed in molten zinc, where the zinc and iron react chemically to form a dense layer of zinc-iron alloy and pure zinc on the surface. This galvanized coating not only provides excellent corrosion resistance, but also resists erosion from harsh environments such as moisture, salt spray, and acids and alkalis, significantly extending the springboard's service life and improving its wear resistance.

Performance Advantages

High Strength and Load-Bearing Capacity: Utilizing high-quality steel as its base material and undergoing rational structural design and processing, Hot Dip Galvanized Steel Springboard boasts high strength and rigidity, capable of withstanding significant weight and impact, ensuring safety and stability during construction.

Fire Resistant: The inherent fire-retardant properties of steel ensure excellent fire resistance, effectively reducing fire hazards and safeguarding personnel and property on construction sites.

Easy Installation: Its standardized design and accompanying connection devices make installation and removal of the springboard simple and quick, improving construction efficiency and reducing labor intensity.

Wide Applications

It is widely used in aerial work platform construction in industries such as building exterior wall construction, bridge construction, ship repair, and the petrochemical industry. Whether in land-based construction projects or offshore projects, Hot Dip Galvanized Steel Springboard demonstrates exceptional performance.

With its superior performance, reliable quality, and wide applicability, Hot Dip Galvanized Steel Springboard has become an indispensable tool in modern construction.

TAG:

Related News

Why Hot Dip Galvanized Steel Springboards Are Essential for Construction Projects